Computational Fluid Dynamics (CFD)- Pump Station

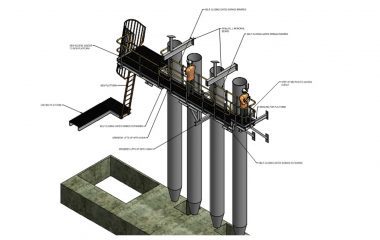

Pump Station Computational Fluid Dynamics (CFD) of Inlet and Discharge Manifolds

Location: Nyah, Victoria

Timeframe: August 2016

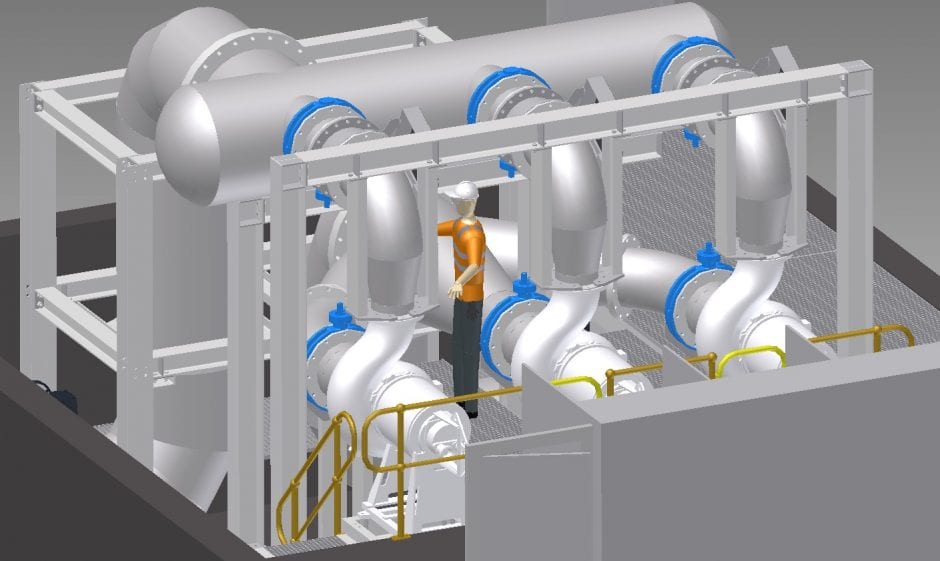

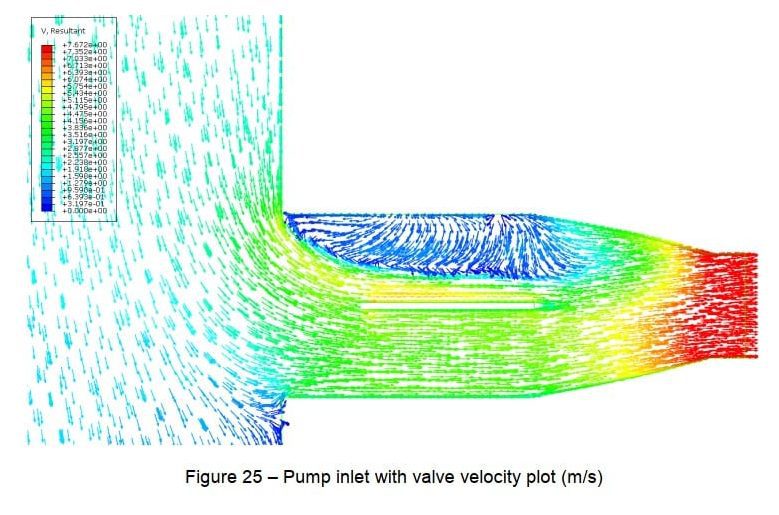

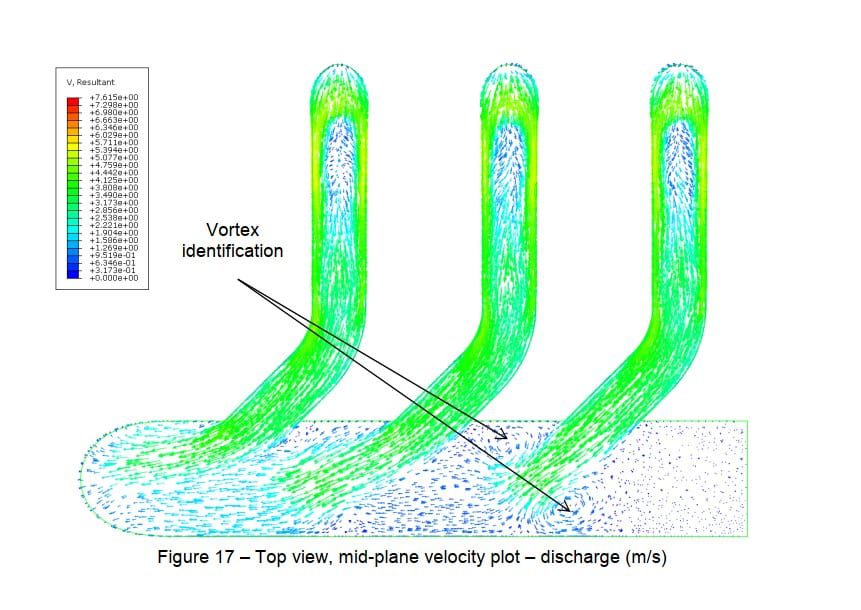

Challenge: The client required a pump station to be changed from one large pump to 3 smaller pumps operating in parallel so that operating low flow rates would be more efficient. Unfortunately, the space available to connect the three pumps was rather limited. Therefore the inlet and discharge manifold design needed to be optimised to avoid excessive head loss and cavitation. A Computational Fluid Dynamics (CFD) analysis was performed on the proposed intake and discharge manifolds at the Pump Station. The primary purpose of undertaking this study was to determine any ill effects of upgrading the pumps.

Services: FEA, CFD, Design Engineering

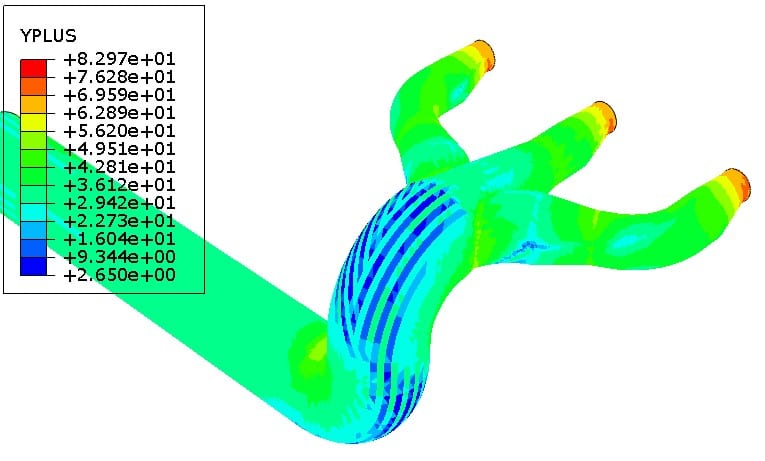

Solution: The pumping arrangement was modelled and analysed with CFD to ensure optimal flow through the manifolds under flow conditions. It was concluded that the design of the inlet manifold resulted in one that could eliminate dangerous flow occurrences such as near inlet vortices, high swirl, and cavitation. However, space limitations did not allow for an ideal inlet approach flow field, and levels of small-scale turbulence had to be tolerated by the pumps.